Industrial & Commercial

Our Blog

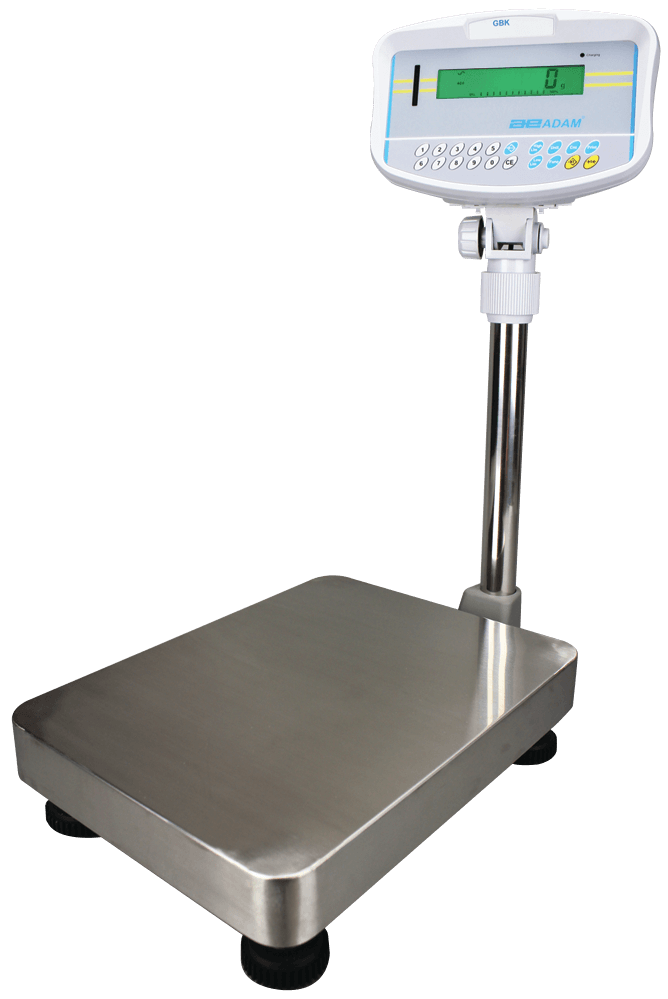

Choosing the Right Platform Scale

Platform scales can be found nearly anywhere: factories, shipping and receiving departments, mailrooms, warehouses and loading docks use them to weigh large, bulky or oversized items, including boxes, shipping crates, pallets, barrels, drums and luggage. In this post, we’ll walk you through one of the harder questions you may have to ask yourself: how do I choose the right platform scale?

The Use of Balances in Materials Testing for Construction

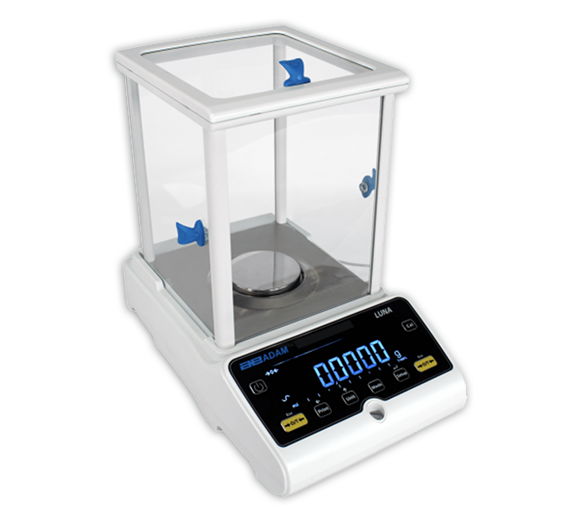

In nearly any industry, the quality of the materials used can often mean the difference between success and failure. This can be particularly true for construction, where failure can have serious consequences. The research and development process typically includes a variety of materials testing applications to ensure the final product meets quality and safety standards. Balances and scales play a critical role in the testing of construction materials.

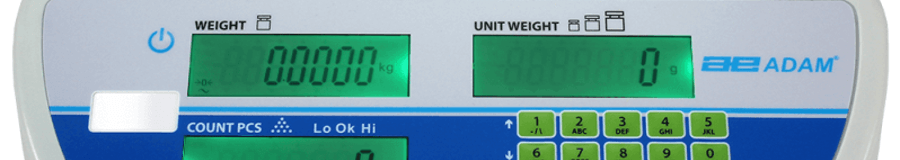

An Introduction to Counting Scales

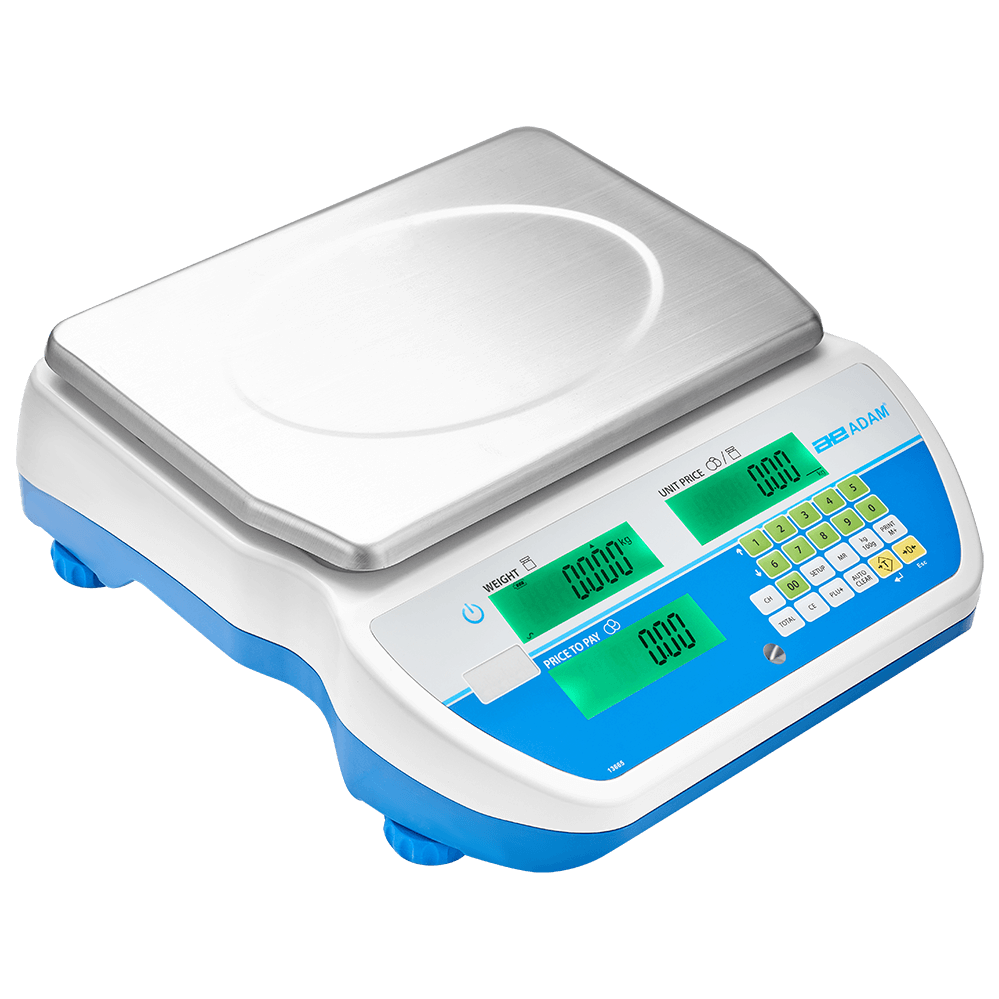

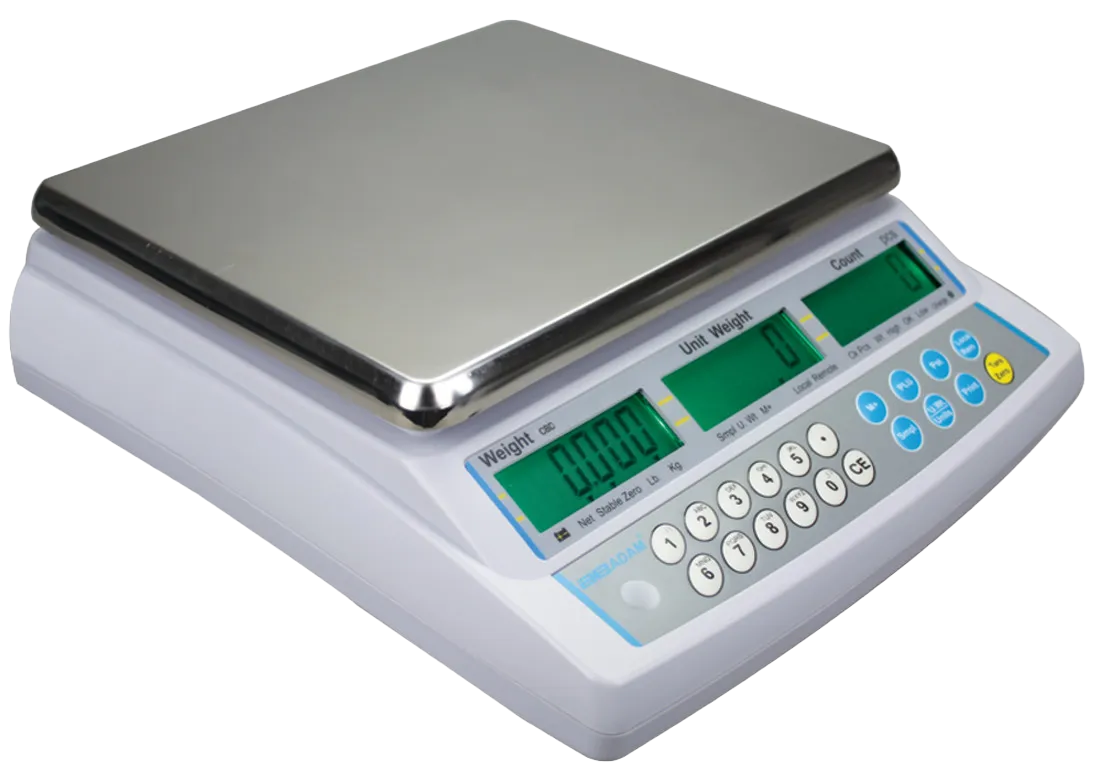

Counting scales are versatile weighing machines that can be used for counting and weighing objects simultaneously. Typical applications include checkweighing, for checking the weight of objects against a pre-set limit to performing accurate parts counting procedures to reduce manual counting. Counting scales come in a variety of sizes that can be used on a worktop bench or a floor respectively. Ideal for quality control centers, retail warehouses, production facilities and factory environments.

Frequently Asked Questions

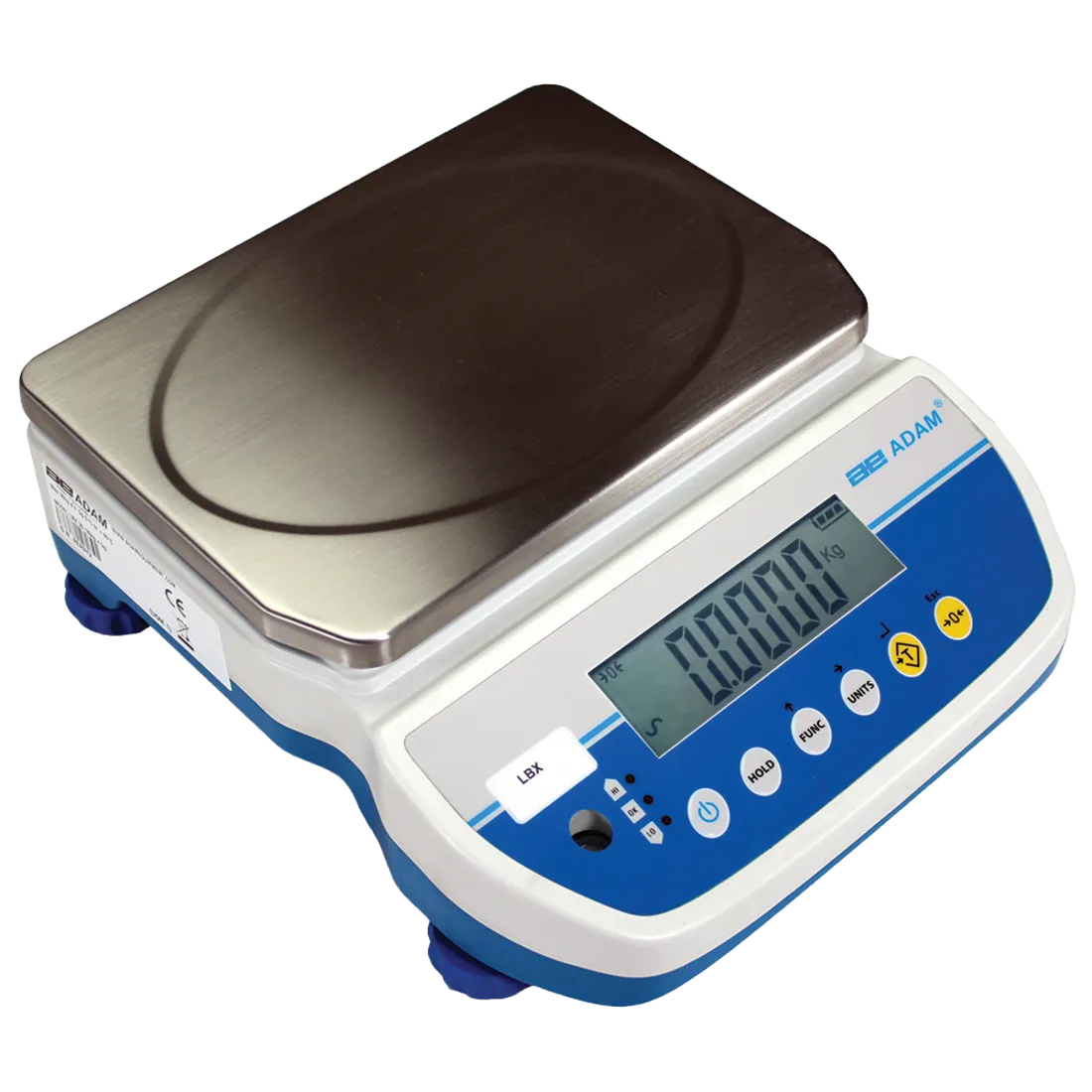

The term 'industrial and commercial weighing scales' broadly encompasses any weighing scale that can be used in an industrial or commercial setting. This includes warehouses, factories, workshops, shipyards, building sites, transport and food manufacturing environments. Commercial and industrial scales are often robust and durable in their design to safeguard against use in demanding environments where knocks, spillages and dirty conditions are commonplace.

Industrial scales can be used in a variety of diverse ways to help make industrial weighing processes faster, simpler and easier.

- Counting scales can be used for end-of-year stocktaking and inventory monitoring, making long, labour-intensive counting processes much quicker and more efficient. They can also be useful for ensuring that packages containing multiple identical items, such as packs of screws or bolts, include the correct amounts as labelled.

- Industrial scales with checkweighing functions can be used to quickly check the weight of multiple subjects to ensure that they fall between a lower and higher parameter, guaranteeing that your products always remain a uniform weight.

- IP-rated weighing scales are useful for damp, dusty and dirty industrial environments where extra protection is required. They are also perfect for food manufacturing and packing environments because they can be cleaned down with ease to always supply safe, hygienic weighing.

- For weighing larger items such as crates, pallets and barrels, a heavy-duty scale with a high maximum capacity such as a platform scale or weigh beams can be used. To weigh palleted goods while providing safe, secure transportation around a warehouse or shipping department, a pallet truck scale can be used.

By law, trade approved scales are required for the determination of mass in commercial transactions. This means that any industry which sells a product with a price that is directly related to its weight needs to use trade approved weighing scales. Some examples of products that require the use of trade approved industrial scales are bottled goods (such as alcohol and animal feeds), packaged products that are sold by weight and certain food items (including meat and fish).

Violators of the law risk fines or even jail time. Trade approvals are in place to protect the customer and ensure that they receive the correct amount of goods that they've purchased.