In nearly any industry, the quality of the materials used can often mean the difference between success and failure. This can be particularly true for construction, where failure can have serious consequences. The research and development process typically includes a variety of materials testing applications to ensure the final product meets quality and safety standards. Balances and scales play a critical role in the testing of construction materials.

Why Do We Test Construction Materials?

Materials testing measures the characteristics and behavior of substances like metals, masonry, concrete or asphalt under a variety of conditions. The most obvious reason to test is to make certain that the final product will function as intended and can endure the stresses of that function (i.e., will concrete footings support the weight of a two-story building).

Reasons for testing include safety, economics and, of course, simply to ensure that a material is suitable for its intended purpose.

How Do We Test Construction Materials?

Materials testing involves a variety of applications that examine composition, physical structure and chemical properties. While the specific tests vary by industry, common tests include specific gravity (also called relative density), unit weight tests, density determination, compression strength, flexural strength, tensile strength, elasticity, permeability, thermal expansion, drying shrinkage and heat capacity.

Adam Equipment’s new can be used to determine the specific gravity of cured samples, such as concrete or asphalt. Specific gravity is the ratio of a substance’s density to the density of a liquid such as water (if the sample substance is a liquid or solid) or air (for a gas).

For field use, the CKT and Highland are equally effective when used with a weigh-below hook, but with the added bonus of an internal rechargeable battery for portability and use onsite.

To utilize the Luna LBL Heavy Duty Precision Balance for specific gravity testing, a sample is first weighed on the balance’s pan and the result is recorded. Then, with Luna LBL placed on a tabletop with a cutout, the sample is placed in a basket attached to the balance’s weigh-below hook and lowered into a container of water below. The balance records the weight of the submerged sample, compares it to the first result and calculates the sample’s specific gravity. The same process can be used to determine liquid density, as well.

Concrete – a composite material, which means it’s made up of several different ingredients – is a prime example of a product whose quality depends heavily on materials testing. Fine aggregates (such as sand) and coarse aggregates (gravel or crushed stone) comprise the bulk of concrete’s volume, along with water, cement and air. The combination and types of the aggregates determine the concrete’s density or hardness.

The ratio of water to solid ingredients is critical: without enough water, the concrete is too thick to pour; too much water, voids form as the water evaporates and weaken the structural integrity of the concrete.

Testing the specific gravity is a way to ensure the reliability of concrete to handle weight without cracking or crumbling.

Click on the infographic above to download

Another common construction test concerns the unit weight (density) of a material such as freshly mixed concrete, which measures the weight of the material required to fill one unit of volume. Unit weight is expressed as the weight of a material (in pounds) per volume (cubic foot or cubic yard): pounds per cubic foot (lb/ft3) or pounds per cubic yard (lb/yd3).

|

|

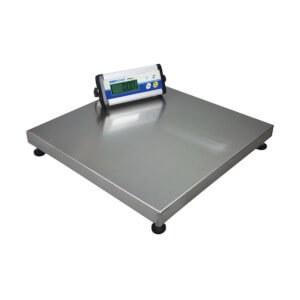

Adam’s versatile CPWplus range includes bench scales, platform scales and wheeled scales that are rugged enough for construction site use. With capacities up to 660lb/300kg, CPWplus is ideal for determining the weight of construction materials. For transportation and on-site use, an optional carrying case for the CPWplus features a durable, locking hard shell case with a die-cut foam insert that allows room for accessories that come with the scale.