Calibration weights are deceptively simple. Aren’t they just a piece of metal? No, they’re not. Calibration weights can truly make or break your weighing results, which is why it’s crucial to avoid these common mistakes when using them.

What Are Calibration Weights?

Calibration weights are blocks of finely crafted metal intended to perfectly emulate a specific weight value. A 1kg calibration weight must weigh as close as possible to what’s globally considered the “true kilogram,” as well must a 1g weight weigh as much as what the world accepts as the true gram.

These weights are used to train your scales and balances so they provide the correct weighing result every time. Though most scales and balances only require one or two weights for calibration, it can be worth purchasing more weights so you have a method of verification.

For example, if your only requires a 100g weight for calibration, you may want to purchase a 1g weight anyways, especially if your most weighed items measure around that result. Before important weighing sessions, you can place the 1g weight on the pan to guarantee your balance will give you the correct result – if not, take the time to calibrate.

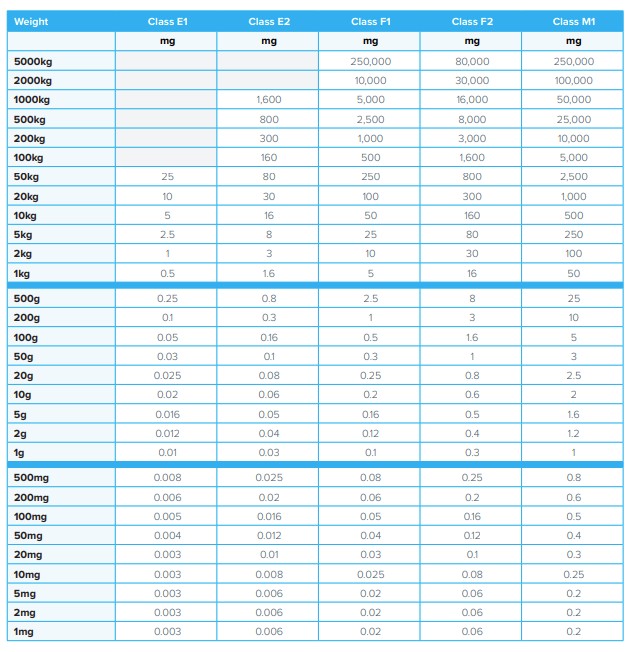

Choosing the Wrong Calibration Weight Class

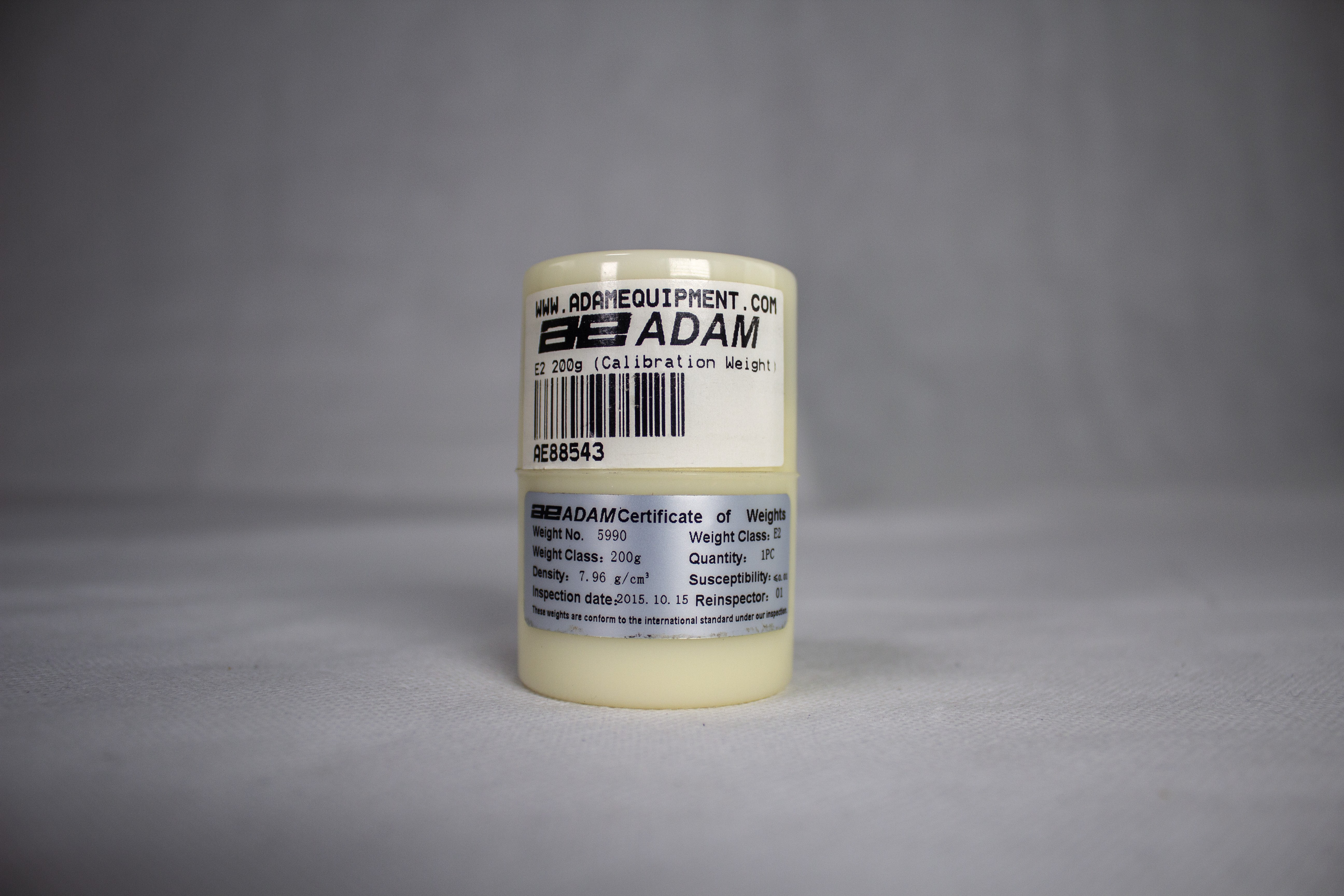

Adam Equipment offers OIML calibration weights, both in sets and individually. Which ones do you need?

OIML weights are grouped into classes. Adam offers OIML classes E1 through M1. OIML E1 is the most precise and accurate weights available on our site. They’re made from finely crafted stainless steel and are perfect for verifying weights as low as 0.01mg or calibrating semi-micro and analytical balances like our , and .

Here’s how you can decide:

• OIML E1 – Ideal for semi-micro balances with readabilities of 0.00001g (0.01mg).

• OIML E2 – Perfect for analytical balances with readabilities from 0.0001g (0.1mg) to 0.00001g.

• OIML F1 – Useful for analytical and precision balances with readabilities from 0.001g (1mg) to 0.0001g.

• OIML F2 – Great for precision balances with readabilities of 0.001g and up.

• OIML M1 – Ideal for compact balances and bench scales. M1 weights made of cast iron are used for high-capacity floor or platform scales.

Of course, perfect isn’t possible, so it’s the manufacturer’s obligation to provide you with the knowledge of how much you could potentially expect your weight to be “off” from perfect, also known as weight tolerances:

This is quite a simplification. For a more detailed explanation, see our other blog, Weighing in on Calibration Weights.

Don’t get caught using the wrong calibration weights – do your research so you get the best ones for your scale or balance.

Touching Calibration Weights with Bare Hands

Test weights, especially OIML E1, are so finely and accurately crafted that touching them with your bare hands can degrade the metal over time and cause them to become less precise. This is because the oil on your fingers, also known as sebum, is slightly acidic, with pH ranging from 4.5 to about 6.2.

With bigger calibration weights the impact may not be as noticeable, but it can become a serious problem the smaller they get, down to the 1mg weight we offer in some of our weight sets for verification purposes.

Instead, we recommend using cotton gloves with bigger weights and tweezers for smaller weights. This way you’re preventing skin-on-metal contact and your calibration weights will stay accurate and precise for longer.

Dragging Calibration Weights Across the Pan

When placing and lifting a calibration weight, it’s easy to drag or shift it across the pan, whether it’s to get it into the right position or just accidentally. However, it’s important that you place and pick up your calibration weight directly up and down, without dragging it.

The first reason is that the metal-on-metal friction can lead to static electricity building up. With more sensitive balances, this can begin to affect your weighing results. You may see your weight readings drifting or being unable to settle. The second reason is dragging your calibration weight can cause scratches to the surface that, like the oil in your fingers, can degrade the weight over time.

If you notice the effects of static electricity and you know it’s not caused by your calibration weights, we recommend investing in Adam’s , which neutralises static electricity.

Not Allowing Calibration Weights to Acclimate

Metal expands in the heat and contracts when it’s cold. If your calibration weights have been languishing in a stuffy closet the AC doesn’t reach and you bring them into your 17-degree laboratory, they’re not going to be as accurate as they could be.

Ensure you’re always giving your calibration weights time to reach room temperature before use. This helps guarantee they’re at the same level of expansion and contraction as your balance’s hardware.

Improperly Storing Your Weights

Unfortunately, you can’t just leave your weights in any-odd place. Some main environmental factors to keep in mind are:

- Temperature – try to keep your calibration weights stored at the same temperature you’re likely to use them in. That way, the acclimatisation period will be shorter. Avoid placing them in direct beams of light.

- Humidity – If there’s too much humidity, the moisture could accumulate on the calibration weights and lead to corrosion over time.

- Stability – The last thing you want to do is drop your weights, damaging them and making them less effective. Store them in a stable location unlikely to move.

- Dust – Adam recommends storing your weights in a container or bag, not just loose. This prevents dust accumulating and adding more weight.

- Contact – keeping the weights in a box or individual bag prevents the weights themselves from touching each other.

Cleaning Weights Too Harshly

If you’ve already touched your calibration weights with your bare fingers or they’re covered in dust, you can still perform some damage control. With a soft brush, microfibre towel or compressed air, you can gently brush, wipe or blow away the offending particles. There’s no need to use harsh cleaners, soap or even water (truly, if it’s THAT bad, it might be best to invest in a new weight).

After cleaning, inspect the weight for lint or particles left behind. Then, let it rest to remove any static charge that could have built up in the process. Avoid touching the cloth or brush with your hands so you don’t contaminate them with your finger oils, though it’s good practice to clean the brush or cloth anyways.

Need help figuring out which calibration weights are right for you, or whether you’re handling them properly? We can help with both. Contact the Adam team here.