Charcuterie boards are all about balancing beauty with flavor. From producing each component to caterers carefully arranging them on the board, scales and balances are crucial. This blog will outline the ways scales and balances impact every element of a delicious charcuterie board.

Manufacturing & Grocery

Cheese

The perfect meat and cheese combination depends not only on the desired flavor profile but texture as well. Brie offers a stiff rind and creamy, soft center, while gruyere is hard throughout. Likewise, soppressata is typically cut so it’s thick and chewy, while prosciutto is meant to be thin and papery – and they’re both pork.

Cheese grows bacteria quickly if proper moisture levels aren’t maintained – and though blue cheese contains mould (the same mould that makes penicillin), you don’t want it growing unintentionally. To help guarantee cheese stays in the right moisture range, tools such as Adam Equipment’s perform quality control throughout the development process.

Cheeses meant for purposes like charcuterie boards (as opposed to being used within another product) are tested for moisture content particularly after the curds have been pressed and shaped into wheels, to make sure it’s ready for aging, and then frequently throughout the aging period.

Cheddar, for example, should contain no more than 39% moisture. A few batches will need to be sacrificed for testing, since it’s best to use a true representative slice, as if someone were cutting it for charcuterie. Alternatively, a tool could be used to poke a hole in the wheel to retrieve a slice that way, which ensures the center is reached and tested. The slice is placed on the PMB’s pan, which would weigh the sample, then heat it up until it’s dry and weigh it again to provide a moisture percentage. This is called the loss-on-drying method. The PMB is much quicker and doesn’t need as large of a sample as traditional moisture testing with an oven, saving time and product.

Meat

Cured meat is (arguably) the pièce de résistance of any charcuterie board. Curing refers to salting, aging and drying uncooked meat so it reduces moisture, which lends it a significantly longer shelf-life than raw or cooked meat. There are many regulations on curing meat that help ensure public health and safety, including monitoring the weight ratio between cured and uncured meat.

Have you ever ordered an 8oz ribeye and received a cooked meal that looks like it weighs much less? The 8oz is based on the pre-cooked weight, which includes all the juices and moisture from the meat. Both cooking and curing dry out these juices, and thus reduce the weight. In fact, it’s against regulations for most cured meats to weigh the same as or more than the uncooked product, and some must be a specific percentage beneath. Dry cured ham, for example, must weigh 18% less than the ham before curing. This requires that the ham be weighed both before and after – the perfect job for an NSF-certified washdown bench or floor scale like Adam Equipment’s IP68-rated .

Deli Meat & Cheese

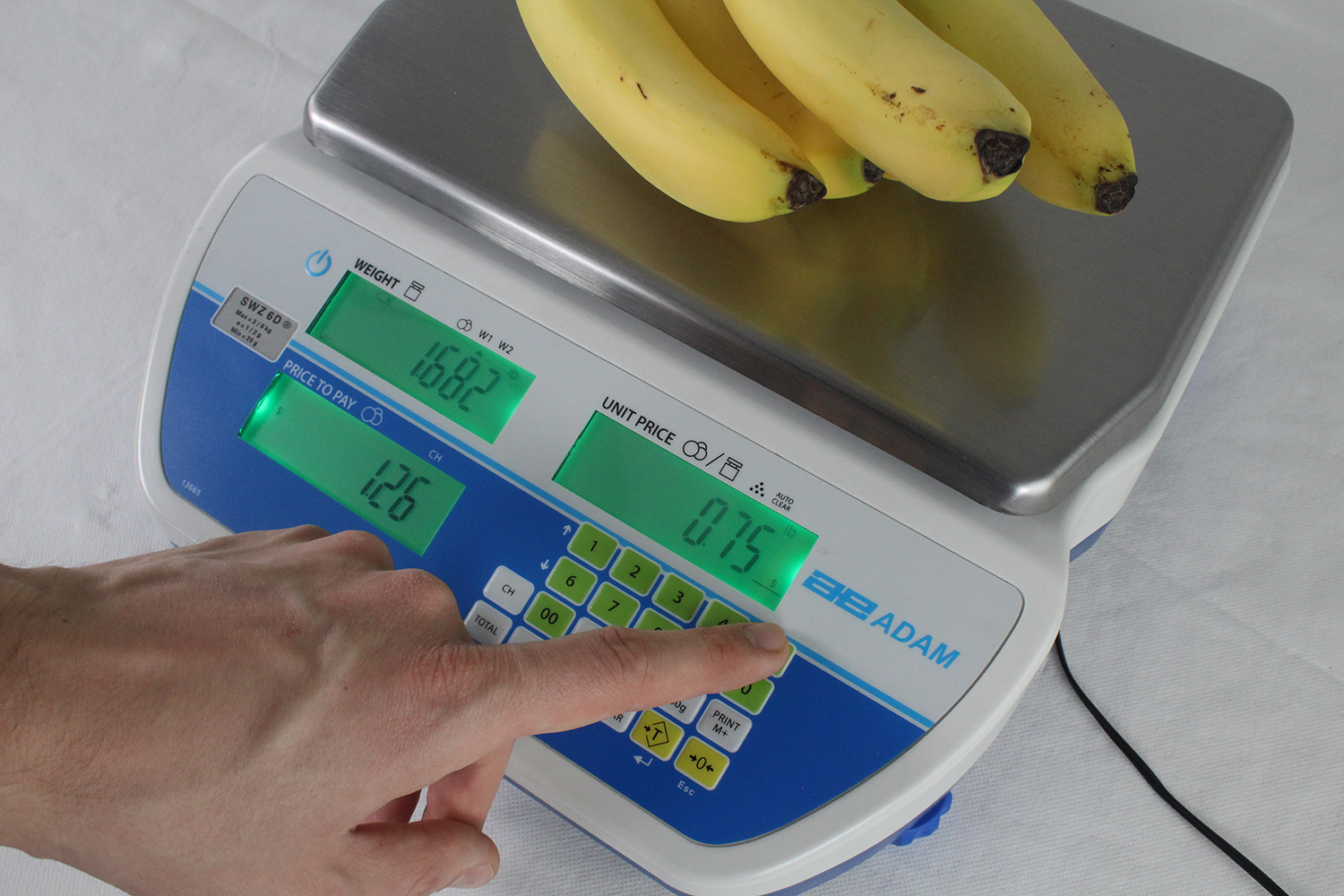

Deli meat and cheeses are prepared the same way as ones outside on the shelves, the only difference is instead of taking the entire package, customers can request a specific weight of sliced product. Selling meat and cheese by weight in a deli legally requires the use of a trade-approved scale. For larger and messier orders, Adam’s is a great fit, while most small to mid-size orders are easily handled by the . The Swift uses a memory system to store and recall up to 161 frequently purchased products and calculate the price to pay by weight. To figure out if you should use a regular trade-approved scale or if the Swift would be your best fit, check out our blog on the topic.

Fruits & Veggies

Fruits and veggies are the perfect way to liven up any charcuterie board with bright, eye catching colors and fresh flavors. Customers will typically purchase fruits and vegetables either packaged or loose. Both require scales, but for different reasons.

Packaged fruits will have been weighed using a trade approved checkweighing scale such as Adam Equipment’s . Since fruits and vegetables aren’t all uniform sizes, checkweighing scales ensure each package weighs approximately the same amount. The CKT-M’s display changes color when the product is less than, within or over set limits. This ensures that each package can be the same price.

For loose produce, like bell peppers, apples or melons, trade approved scales are once again the best option. They make sure that customers are paying proportionally for what they’re taking – the largest bell pepper would of course cost more than the smallest.

Crackers, Breads & Nuts

Crackers, bread and nuts are great for elevating a charcuterie board by adding a crunchy texture.

Both crackers and bread are baked goods, created from flour, sugar, salt and a variety of other ingredients. To keep each batch consistent when manufacturing bread and crackers in bulk, scales are used to weigh each ingredient. Volumetric measurements in baking can lead to errors, as it depends on how densely packed the ingredients are. Since weight ignores density, it’s the perfect measuring system. Select crackers and breads during production would be chosen as quality control samples and weighed, to help guarantee that each batch are sufficient. This could be done with NSF-certified scales like Adam Equipment’s which offers capacities between 4kg and 32kg with readabilities from 0.1g to 2g.

Nuts are roasted in batches, and it’s important to ensure that approximately the same number of nuts are cooked at the same time. This helps guarantee an even, consistent roast, as the air circulation, heat absorption and the amount of surface area exposed impacts how long they take to roast. 100 nuts in a batch will cook a lot faster than 200. The can help by basing the batches on weight.

Jams, Jellies & Sauces

Whether sweet, savory or sour, once a dip is chosen, the charcuterie board is complete. Each jar of dip boasts a uniform taste and texture with carefully controlled ingredients, particularly in jams and jellies where they’re primarily fruit based. Each jar must have approximately the same amount of fruit, measured by, you guessed it, a washdown or checkweighing scale.

Restaurants & Catering

Charcuterie boards are popular offerings in restaurants and wineries, they’re also frequently catered for large parties. Charcuteries are presented and eaten from one plate or board, which means proper portion sizes are important. There must be enough opportunities for each person eating to enjoy the variety of flavors and textures presented. Below is a chart which outlines how much of each component should be included depending on how big the party is.

If the charcuterie board is an appetiser, it’s recommended to lean on the lower side of each range. If it’s meant to be the main meal, aim for the higher end to make sure each person leaves with a full belly. Knowing what the charcuterie board is intended for will help prevent food waste and improve customer satisfaction.

Adam Equipment’s NSF-Certified , with capacities between 3kg and 30kg with readabilities from 0.5g to 5g is the perfect instrument to measure out the perfect portions. The Latitude also offers a 210-hour battery life, plenty of juice for up to 26 busy working days.

|

|

1 Person |

2 People |

5 People |

10 People |

20 People |

Meat |

57-85g |

113 – 170g |

283 – 425g |

567 – 850g |

1.1 – 1.7kg |

Cheese |

57-85g |

113 – 170g |

283 – 425g |

567 – 850g |

1.1 – 1.7kg |

Crackers |

28 - 57g |

57 – 113g |

142 – 283g |

283 – 566g |

567g – 1.1kg |

Fruits & Veggies |

28g of each |

57g of each |

142g of each |

283g of each |

567g of each |

Nuts |

14 – 28g |

28 – 57g |

71 – 142g |

142 – 283g |

283 – 567g |

Dips |

1 tbsp |

2 tbsp |

5 tbsp |

10 tbsp |

20 tbsp |

From manufacturing to charcuterie board, scales and balances have encountered every component. To find the right one for your application, contact the Adam Equipment team, and we’ll be happy to help.