Analytical and precision balances are crucial in any laboratory, yet it’s not exactly easy to ensure you’re always getting the most accurate results. In this blog, we’ll discuss the top 18 challenges that come with lab weighing, and how extra prep and extra attention can help you overcome them.

Environmental Challenges

So much of your environment is out of your control that it can be especially frustrating when it begins to impact your lab weighing. You may notice your results drifting, jumping or taking longer to stabilise. If this is the case for you, consider which of the factors below could be your issue. Adam offers a few accessories to help.

1. Air Drafts

Unless you’re working in a completely airless room, air is a constant and nagging challenge in a laboratory. Wind from an open window, the air conditioning, even breeze from someone walking by can all cause weight readings to drift or jump unexpectedly. Air not only tries to get underneath the weighing pan to bolster it up, it also adds force to your samples and makes them register as artificially heavy.

Air drafts are such a prevalent issue that semi-micro, analytical and many precision balances feature built-in draft shields to protect against it. This is why you need to ensure that your draft shields are completely closed during lab weighing, and, if you can help it, the balance is placed in a location less prone to errant gusts.

2. Vibrations

Vibrations are also surprisingly constant. Construction down the street, booming music, footsteps not only in the room but also in the building as a whole cause vibrations. We get used to it, but your balance can’t. Adam offers an accessory designed to mitigate the risk of vibrations, the . The AVT is a double-framed table, the centre frame of which supports a 100lb/45kg granite block. When balances are placed on the granite block, they’re more grounded and less susceptible to vibrations.

3. Temperature Changes

Have you noticed that your readings seem less accurate after you’ve moved your balance to a different location? That might be because of the temperature difference. You can’t bring your balance from a toasty 72°F / 22°C room to one that’s a cool 54°F / 12°C and expect to get accurate results right away. All highly precise laboratory balances need to acclimatise to a new environment before they’re used – we recommend at least 12 hours.

4. Static Electricity

If the humidity in your laboratory is below 40%, static electricity is more likely to form. You can cause static by dragging metal, powder or fabric samples across the metal weighing pan when you’re setting them down or taking them away. To help prevent this, always set and lift samples straight up and down.

Some samples can be pre-charged with static before they even touch the balance. For cases like this, we recommend Adam’s , which neutralises static electricity. All you have to do is turn it on and face it toward the balance; it’ll neutralise static in your samples and any that has built up in the weighing chamber.

Machine Challenges

These are challenges presented by something on or in the balance itself.

5. Poor Calibration

Lab balances require frequent calibration to remain precise and accurate over time. If you don’t calibrate frequently enough, your results stop being reliable. Some balances offer both internal and external calibration, while others only offer external. Both have their pros and cons and bring their own challenges.

If you’ve moved the balance to a new location recently, let the balance warm up for 12 hours before calibration or use. When internally calibrating, especially if it’s scheduled to occur when you’re not present, guarantee that the draft shield is completely closed and there’s nothing on the weighing pan. If the draft shields are open or something is left on the pan, calibration will force the balance to accommodate around it, which can lead to inaccurate results.

External calibration requires test weights, which need almost as much thought and care as your balance. Because someone must actively perform external calibration, there are different risks. Stand straight, feet planted, without leaning on the benchtop, to avoid un-leveling or shaking the balance with your movements. Only open and close the draft shields when placing and removing the calibration weight as prompted by the balance. Don’t drag the weight across the pan, lift and set it down directly, to prevent generating static.

Calibration isn’t a difficult process in itself, but there’s a lot of ways you can get less-than-satisfactory results, which is why Adam provides calibration services at our facilities.

6. Wrong Balance

Sometimes, if you’re unsatisfied with your laboratory balance, the solution can be simply to invest in a more suitable machine for your lab weighing. For example, our are highly precise and accurate, with readabilities as fine as 0.001g. They come with a small, removable draft shield and extra protection against shock loading and drops. It’s a simple and effective machine, but you may be at a point where you need something more advanced.

Our new can provide you with the same or better readabilities along with other benefits that are helpful for any laboratory. For example, a large, built-in draft shield for more guaranteed protection with any size sample. It boasts an expansive, colour-changing display so you can see more info all at once, as well as the ability to store ingredients in its internal memory. Both the Highland and the Polaris PPB are precision balances, but one may be better suited for your lab than another.

Not that the best choice is always the more precise, fancier balance! offer 0.01mg readabilities, which would be too fine for an application only requiring results to the 0.01g. In that case, you don’t have to suffer the sensitivities that come with a semi-micro balance – try out the Highland!

7. Dirty Balance

Dust, powder, liquid residue and oils can be left behind on the weighing pan without attracting much notice. However, they can build up over time until they begin to influence your results, either by adding a minute amount of weight or by harming the internal mechs. To clean your balance, we recommend using a microfibre towel or a soft-bristled brush to remove solid debris. Then, if necessary, using ethanol as a cleanser. Ethanol evaporates quickly without leaving behind a residue.

8. Levelling

Not all surfaces are created equal, even a flat laboratory benchtop may send a marble rolling. An unlevelled balance can cause the items on the pan to distribute weight unevenly. This can begin to wear down internal mechanisms more quickly, like driving on a low tyre. All Adam lab balances feature a built-in levelling bubble, and many offer individually adjustable feet. Twist the feet up or down to ensure the bubble is directly in the middle of the circle and that the balance is sitting stable on your benchtop, without a wobble.

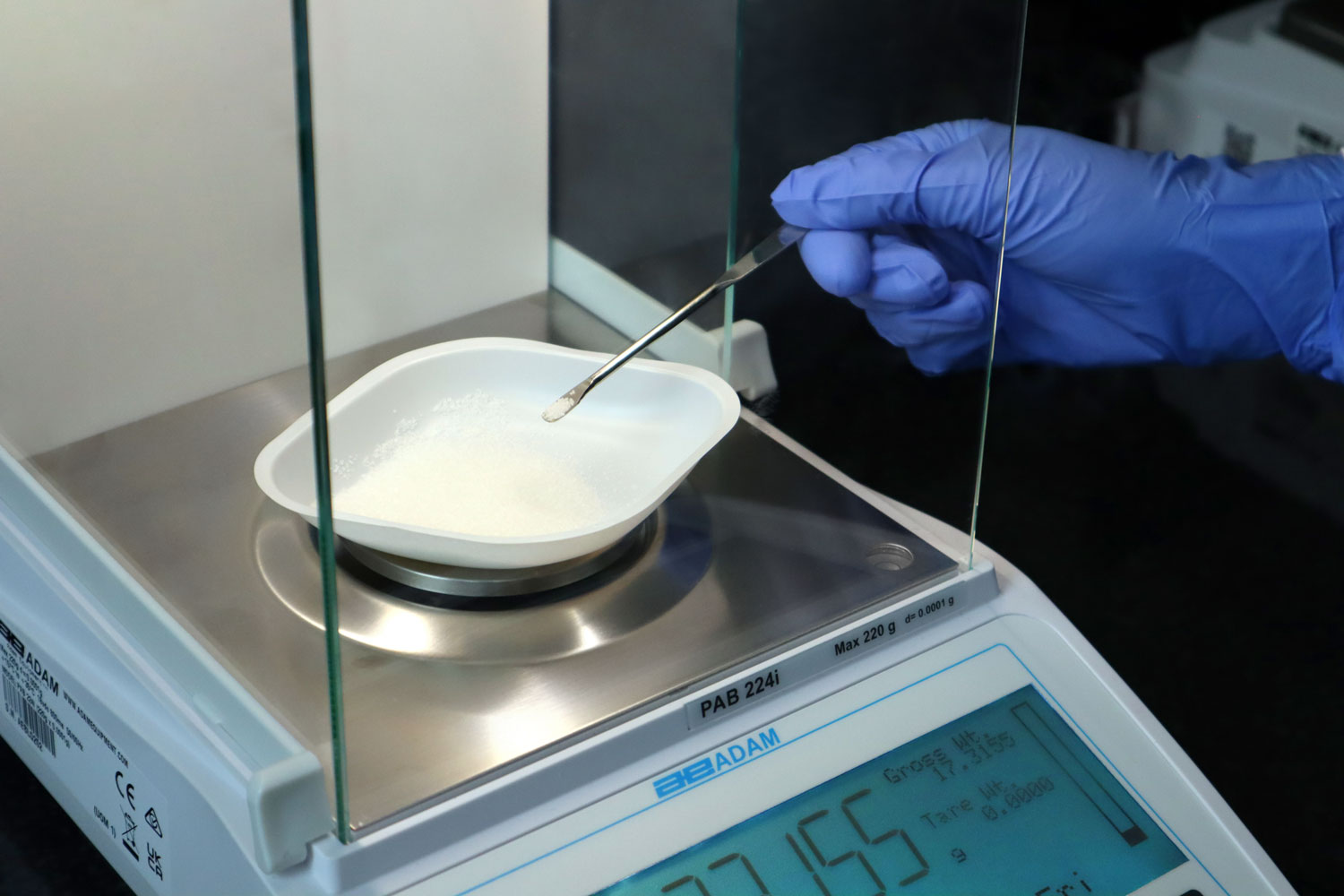

Sample Handling Mistakes

Even the way you handle your samples can impact whether your balance is doing its best work.

9. Weighing Hot or Cold Samples

One rule of thumb for weighing is to have your balance, sample and containers all the same temperature before weighing (calibration weights as well, when externally calibrating). If your sample is significantly colder or warmer than the balance, it can cause convection currents in the draft shield, which can be as damaging to your results as not having a draft shield at all.

Unfortunately, even if you’re careful about keeping your samples, balance and containers all the same temperature, the balance itself begins to heat up over long weighing sessions. Adam’s new offers a solution to this with its new Air Diversion Technology feature. You can read more about it in our recent blog.

10. Static Charged Powders

We mentioned that low humidity can make it more likely for static electricity to develop in a laboratory environment. Powder samples are especially prone to static, because the particles generate friction. If you weigh a static charged sample, you can introduce static to the weighing chamber, making it more difficult to get rid of. Consider placing your samples in front of the ABI-1 ioniser before weighing.

Technique and Procedural Errors

Sometimes, it’s just not the balance’s fault! These errors can be caused by using the balance incorrectly. Unfortunately, this means that mistakes may occur inconsistently, depending on who is operating and when. This can make them harder to recognise. Ultimately, the main way to prevent technique errors is training operators effectively!

11. Taring

Taring is simple, but precisely because it’s simple, it can be easy to make simple mistakes. For example, forgetting to zero the tared value before moving on to other non-weighing related tasks. Any remaining negative result will still be there when you turn on your balance, and many go on autopilot and begin weighing as normal.

Another common mistake is not re-taring after changing containers. If you’ve been weighing items using the same type of glass petri dish all day, you might not remember to re-tare if one sample out of the bunch happens to be in a plastic petri dish instead.

Always pay special attention when tared weights are in play to ensure your readings are as accurate as possible.

12. Bare Hands

The oils on your fingers are surprisingly insidious, though it’s more likely to be a longer-term issue than an immediate one. Not only do oils add an infinitesimal weight to the samples or calibration weights you’re touching, but they can also start to eat at them and cause deterioration over time.

To prevent this, only touch your calibration weights and samples with tweezers or cloth gloves. Also check to guarantee that there’s no other debris, like lint, dust or string that could stick.

13. Draft Shields

We discussed why draft shields are important for mitigating issues with wind and breeze, but it can be challenging to remember to close the draft shield completely before recording your results.

14. Recording Unstable Readings

Similarly, wait until the display shows the “~” symbol off to the side before marking down weight readings, even if it seems to have landed on a number already. That symbol means that the result has stabilised and isn’t going to change again, making it the most accurate. If your results seem to take longer than usual to stabilise, consider any of the above explanations as to why that might be!

15. Rushing

Slow down! Rushing isn’t conducive to receiving the most accurate results, often leading to mistakes where you might not usually make them. All it takes is a draft shield left slightly open, a tare weight forgotten and suddenly your results aren’t reliable! Don’t let tight deadlines distract you from operating effectively.

16. Transcription Errors

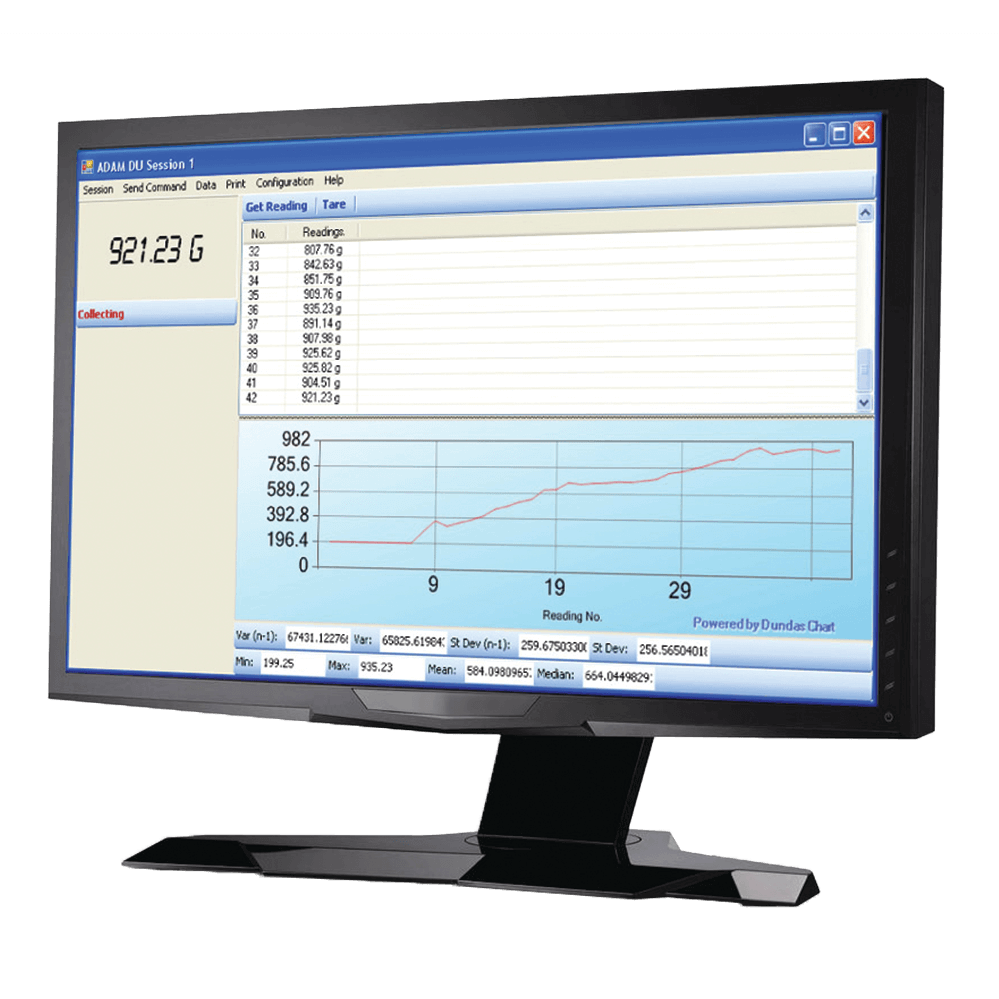

Handwritten records of weight readings are prone to human error, whether from the person recording the readings or the person transcribing them later. Luckily, there are a few other options, such as Adam’s , which prints each result, or the . AdamDU turns weighing results into data, analysing it all on your behalf from up to eight balances at once.

17. Inconsistent Technicians

Training is extremely important for lab weighing to ensure that each technician is using the balance well. Adam lab balances offer the opportunity to monitor your technicians by giving them each their own log-in user code. This means that each printout will record which technician earned the result, and if there any inconsistencies appear, you can catch it quickly and ensure they’re following all procedures correctly.

18. Ignoring Manual

Manuals exist for a reason; they’re the manufacturer’s guide for using the product you’ve invested quite a bit of money in. No guessing is necessary! Follow manufacturer recommendations for type of calibration weight necessary, procedures for different applications, operating temperature requirements and more. You can find manuals for your Adam balance in multiple locations on our website. On the product page, the individual model pages and the Support page dedicated to manuals!

Lab weighing is tough! But Adam can help – contact the Adam team today.