Many business owners and managers dread the end of the year stock-take. Difficult, tedious and holding you back during a busy season, inventory checking is a necessity for good tax returns and a well-run business. There are many ways to save time and money, and to stay organised to ensure stock-taking season won’t be a frustrating experience. We will outline how warehouse scales and balances can help you streamline the process.

#1 Consider what you are weighing before choosing a scale

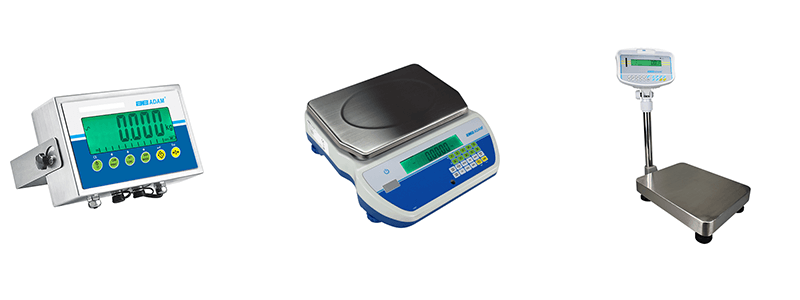

If you don’t already have a warehouse scale, or if you’re unsure your scale will do, think about your inventory process and the volume of stock you will need to count. Perhaps your inventory pieces are too small for you to need a large scale most of the year, but increased capacity is really useful during inventory taking. If so, a bench counting scale like the CBD is perfect for you: this small scale can do parts and check counting, and it can be connected to a remote platform to increase its capacity. Depending on your scale, and the size of your inventory, you might not be able to fit everything you want to weigh on the weighing pan. You might be tempted to get a high capacity platform scale to ensure you won’t overload, however we would urge you not to get a scale of this size if you weigh small items like paper clips. If your business deals in very small items, even if you have a lot of them, you need a scale that can accurately measure the small variations or you will lose money. Make sure the scale is fully adapted to your products. You can also pair a good counting indicator like the GC or AE 403 with a platform scale. It won’t increase the scale’s readability, but it can turn a simple platform into a powerful counting tool.

#2 Use the weighing functions on the scale to streamline checking processes

Take a good look at your inventory and find the features that will make the process quick and efficient. Checkweighing and/or parts counting are likely to be the main applications you will be looking for and it may be worth investing in a checkweighing scale should you need a high performing scale for this particular use. Some scales have an accumulation function that allows you to keep adding on to the weight, even if their capacity doesn’t allow them to have the entire weight on the platform. Another useful function is automatic parts optimisation for more precise results. Take advantage of USB and RS-232 interfaces to streamline the data collection process and to transfer data to your computer so you don’t have to input it manually. Some digital scales have LED displays that let you know with a glance if you’re over, under or within your count/weight range; making the counting process highly visual helps you stay organised. There are a lot of things scales can do besides weighing items nowadays, and being aware of your scale’s features can help you streamline inventory taking as much as possible. You paid for it, you might as well take advantage of all the features.

#3 Configure your scale against what you are looking to weigh

Some scales have useful features that allow you to set a sample size, preset the tare function or pick the digital filtering. Programming your scale ensures it is optimised for the weighing tasks it will perform, saving time and money. Some scales and weighing indicators can be connected to multiple scales and platforms to be even more efficient. You can define the sample size using a numeric keypad, or simply put the items on the scale and let it count or checkweigh the initial sample. Numeric entry is also useful to organise items. Some scales have PLU (product look up) memory that is very useful if you wish to store fixed piece weights for various items.

#4 Calibrate your scale before use

Make sure you calibrate your weighing scale before starting the inventory taking process. If you use the scale to manage your inventory year round, you want to make sure it’s calibrated frequently.

#5 Choose the right scale for your needs

Our weighing scales and balances are delimited by markets and type. Take a good look at the feature icons, as they can tell you if a feature you need is offered at a glance. We have industrial weighing scales for big warehouses and heavy products, smaller counting scales for small parts, and bench scales and floor scales for more versatile inventory. Don’t hesitate to contact us if you’re unsure which scale is best for your application.