Metallurgy is a wide ranging field, but at its core remains the study, modification and use of raw metals for a variety of diverse applications. In this post, we’ll focus on the heavy-duty side of metallurgy and how platform scales are used throughout the field, as well as how to pick the right scale for your needs.

Please note that to work, a platform must be connected to a weighing indicator. Adam indicators and platforms are compatible in a wide variety of configurations. If you order a platform scale, make sure you have an indicator to go with it!

How to Spot a Reliable Weighing Platform

Working with metals can be a very physically demanding job in rigorous conditions, so it’s important to combine precision with durability. A scale that breaks after a week is useless, no matter how precise it is. That’s why platform scales are built to withstand demanding conditions day after day.

Not all weighing platforms are created equal. When purchasing a platform scale, make sure that they are thick enough to withstand the weight you will place on them. A thicker platform is more durable as well. Adam Equipment's heavy duty platforms are all constructed from thick plates to ensure a long-lasting, reliable product even in the toughest conditions, including outdoors.

Always check the material the platform is made of. Cheap materials can offer less protection even if the platform looks thick.

Measuring Propane Consumption

Some forges use propane for activities like heating and welding. While gauges are available, they’re widely considered to be inaccurate, as changes in pressure do not always accurately reflect the amount of propane left. Propane tanks are usually filled up to 80% capacity to allow for expansion due to heat. This is necessary, but that means that the gauge depends on ambient temperature for accuracy. In addition to keeping track of how much money is spent on propane, weighing propane tanks can help you measure your consumption to not only see if you’re wasting any, but also to ensure you have enough propane for various tasks. No one wants to start the day ready to accomplish an order before realizing there’s not enough fuel.

It’s quite easy to check propane by weight, as most tanks feature both the tare weight and full weight.

Shipping and Receiving

Platform weighing scales are often used for shipping and receiving tasks, so they’re well-suited for sending or receiving raw materials or packaging customer orders. Indicators can be connected to computers and printers to simplify logistics. You can use our AdamDU software to connect and monitor up to 8 different scales simultaneously. When working with heavy materials such as metals, precision is important because shipping can be very costly. It can help a forge determine which shipping methods to use, or how much work it will be to receive bulk quantities for an order. Even if a customer is picking up their order, it can be useful to weigh it beforehand to let them know, especially for tools or construction materials where specifications are required. Platform scales can also be used to check the amount of received material after purchasing it.

Selling Metals

Whether you’re selling scraps you don’t need or you’re buying material in bulk for your next project, a trade-approved scale is necessary for any commercial transaction. Trade approval ensures you get what you pay for, and gives your customers the assurance of accuracy when buying by weight. Legal requirements can vary depending on your location, so make sure to check local laws when purchasing a scale to sell materials by weight. Most trade approved scales with feature the “M” to help you find the right scale for commercial applications. Make sure both the platform and the indicator are trade approved!

Material Consumption

When creating a new piece, it can be useful to start with a specific quantity of metal to make sure you have enough to finish your work. A heavy-duty platform can allow users to measure high quantities without overloading or damaging the scale.

Another reason to measure the amounts you use is to record your material consumption to keep track of costs. If you connect your platform scale to computers, you can follow how much you paid to get material shipped to you, how much you used for a project, how much you sold it for, shipping costs, evaluate whether certain types of orders are worth taking, and if your prices should be raised or lowered. It can help reduce waste and ensure you always have enough raw material to create projects.

Weighing metal is also useful when casting molten metal into molds; it’s always the right quantity, so it reduces waste and time spent working on fixing the object or recasting it.

What are some useful features for weighing scales used in metallurgy?

Enclosed load cells help ensure your weighing platform is protected from dust, small pieces or demanding conditions, especially when weighing outdoors.

Overload protection is useful, as it can help users prevent damages to weighing mechanisms due to accidental overloading.

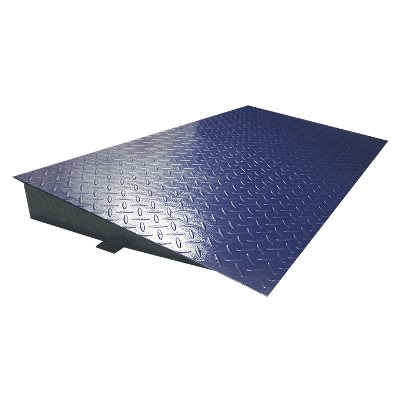

The weighing platform should be sturdy, either made of stainless steel (like our PT, W, GB or GF series) or diamond-plated steel (PT and PTM). Make sure the load cells are well-protected and that the material of the platform can handle the materials you will be weighing.

Shielded cables are a good investment for rigorous conditions. The indicator should always be reliably connected to the platform, and you don’t want power to be cut off in the middle of weighing.

A good indicator is also important. The platform contains the load cell, but the indicator displays results and adds functionality. What kind of indicator you should use depends on your needs. For example, a checkweighing function like in our GK can be useful when measuring specific amounts (such as metal that will be melted down) while a counting function (GC) can help when packaging small pieces. If you work in wet, humid or dusty conditions, consider using an indicator with a rating of IP67 like our AE 403. Some indicators even feature a built-in labelprinter in addition to counting and checkweighing functions.

Most indicators can connect to computers and printers via an RS-232 interface. You can take advantage of this feature to print results or record them into various computer systems to manage inventory, process orders and track material usage over time.

Should I get accessories?

That depends on your needs. Ramps make loading and unloading easier if you weigh heavy objects such as propane tanks. If you mostly measure light loads, they’re not going to make much of a difference. You can also get heavy-duty platform with built-in ramps like our PTM.

Some platforms include wheels and handles for easy transportation. If you plan on keeping the scale in the same area, they’re not needed, but if you work in a large area or often travel to different job sites, it can be very useful, especially since weighing platforms can be quite heavy. If you plan on moving the scale often, consider investing in a travel case to reduce the chance of your indicator getting damaged during transportation.

If your platform has a polished steel surface, you can get a rubber mat to avoid scratching the surface and improve grip. That can be useful for weighing finished pieces with a delicate finish or made of soft metal.

We hope this post was helpful in understanding how platform weighing scales are used in the field of metallurgy. If you need help finding the right scale for your needs, contact us! We’re happy to help. Already using a scale to weigh metals?We’d love to feature your business in a case study.