Epoxy resin is a popular material for a wide variety of crafting and manufacturing applications, from surfboards to dioramas. It may look easy on DYI YouTube channels but mixing and pouring epoxy takes knowledge and a little effort to get right. This blog post will help you understand why you should use a scale to mix epoxy and which ones are best.

What is Epoxy Resin?

While the name refers to a wide variety of products, it essentially means an adhesive plastic polymer that is thermoset: irreversibly hardened by curing, either because of heat or a suitable catalyst.

The chemistry of the resin is adjusted depending on your needs (for example, someone who uses it for woodworking wants a thin, clear coating) and once poured, it needs to cure for a period of time before reaching full strength and hardness. Because it starts fairly liquid and hardens slowly, it’s a versatile material used by manufacturers, craftsmen, woodworking or electronics.

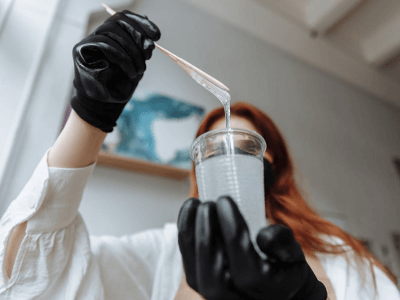

It’s also less harsh than other similar chemicals that can significantly lower the air quality in shops. That being said, please observe proper precautions when using epoxy resin. Wear gloves, a mask, protective goggles and an apron or protective clothing. Make sure your hair or sleeves will not get tangled or dip in the chemicals and that you work in a well-ventilated area.

Why is a Scale Needed?

Epoxy resin isn’t cast or poured by itself. It’s usually mixed with hardener and dye. Industrial manufacturers also sometimes add filler or additives to add or reinforce certain properties. These various components all have different densities, so mixing by volume is very difficult.

To make things worse, an incorrect ratio can lead to tacky resin that does not reach full strength. It can also affect curing times, turning a short project into a long, messy process. Not only can that look bad, it can also lead to the object getting damaged if the resin coat is meant to protect the material underneath (for example, some surfboards are coated with epoxy to protect the softer, lighter material from salt water).

Always check the ratio stated by the manufacturer. If you’re working on a large project, it is recommended to make a small batch to check your measurements are correct and the resin cures according to specifications.

What Kind of Scale Should I Use to Measure Epoxy?

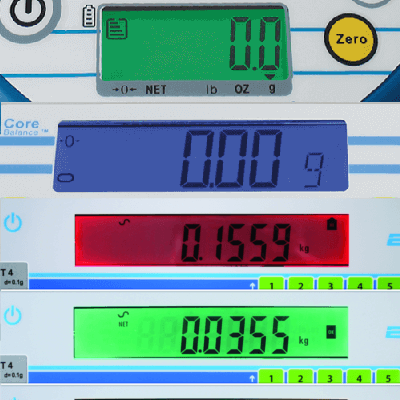

Consider the amount of resin you have to pour to find out the capacity of your scale. Hobbyists and jewelers often use compact balances or bench scales for their precision. Be cautious; because the ratios can be very specific (particularly for dyes, as they are very concentrated), you should get a scale that can show “XX.Xg” for small batches, or “XX.XXg” for recipe development, material testing or research batches. Make sure you scale can do that in all units. Some cheap scales only show that second digit in ounces, but not in grams.

Keep in mind pigments and mixers are very delicate to work with. You should always carefully measure them before mixing and store formulas that work well. Most professional recommend no more than 5% per weight. Some pigments and chemicals can be quite expensive, so it’s important to get a fairly precise scale, or you could waste a lot of time and money creating a batch of resin that is the wrong color or does not cure properly. If you pour or coat bad resin onto a diorama, woodworking, or furniture, you also risk wasting the entire object that was dipped in faulty resin that cannot be removed.

If you’re creating resins for flooring or manufacturing, you might need large weighing platforms or floor scales. They’re not as precise, but they allow you to mix larger quantities in a single batch. You can use a more precise scale to create your recipe, then adjust it using a large capacity scale. It’ll save time and effort on containers and a large batch takes longer to cure.

Make sure the scale you choose is sturdy and highly resistant to spills of adhesives, epoxy and dyes. Some scales, the Aqua washdown scale, are rated IP67 and can withstand chemicals and water jets for easy cleaning. If you’re buying a plastic scale like our CB, consider a removable stainless steel pan or an in-use cover to protect your scale from spills. Try to clean spills as soon as they happen. Epoxy is very difficult to remove once it’s cured and hard deposits could cause drift or add enough weight on the scale to throw off the correct proportions when mixing.

The tare feature is essential since epoxy needs to be poured in a container. Most people tare the container and the resin and add the hardener and dye in the same container to save some cleaning time. Adam scales feature a yellow tare button for quick, easy recognition.

If you’re using large, fixed quantities (always mixing the same materials in the same ratio), consider a scale with a checkweighing feature like our Cruiser bench scales, which include a display that changes color to indicate if the load is over, under or within preset limits. They can produce sounds and lights to indicate when the target weight is reached without needing to monitor the scale closely.

Checkweighing can also be useful for large scale projects such as furniture or dioramas, since you might need a lot of layers before the end of your project. Do not pour all your epoxy at once! At best, you might end up with a lot of trapped air bubbles, which leads to murky visibility. At worse, the chemicals will cure and heat up, smoke and even crack the epoxy.

This is especially important for projects that are done on wood or Styrofoam, since the epoxy could melt through the material. Storing the epoxy in a cold area can make it cloudy or interfere with the curing process, so be patient and measure each layer only after the previous one is completely cool.

A rechargeable battery allows for portable operation anywhere, which is useful for measuring and mixing onsite, or for small workshops where outlets might already be used by other tools. Some scales, like our handy Latitude, can even be powered via USB power sources.

Want to see our scales in action? Check out this case study, where a guitar maker uses a Dune compact balance to measure epoxy and pigments to coat guitars. Do you do large scale work? Our CBK was used by Blastoff to create floor and surface coating.

Need help finding the perfect scale? Contact us, we’re happy to help.