Floor scales play an important role in heavy industry, from mining and construction to production and shipping. They’re tough, accurate and versatile, perfect for weighing raw materials or machinery parts. Let’s take a deeper dive into why you might choose a floor scale for your operations.

What’s the Difference Between a Floor Scale and a Platform Scale?

In the wider weighing industry, floor scales and platform scales are generally considered synonymous. Both terms imply a scale with a large platform and independent indicator that’s typically used on the ground, instead of on a benchtop.

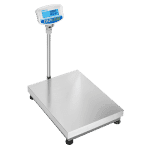

In terms of product classification, however, Adam Equipment considers the two types distinct. Floor scales have lower capacities than platform scales while being more versatile and maneuverable. They also offer a built-in pillar option to support the included indicator, while platform scales are available without indicators and can be mixed and matched. Floor scales are the perfect in-between option for heavy-industry tasks that are constantly on-the-go; not too big for moving around a work site, but not too small to weigh bulk materials.

Built for Tough Environments

Adam floor scales stand strong on mining and construction sites, with capacities between 60kg and 600kg and stainless-steel weigh platforms as large as 800x600mm. While a platform or crane scale would be more suitable for significant loads, floor scales are an excellent mid-range choice for tasks that don’t justify mobilising heavy equipment – like weighing smaller items quickly.

Individually adjustable feet and built-in levels ensure that no matter where you’re setting up shop, your floor scale can work with you.

Worried about the potential impact of coal or saw dust on how your scale operates? Or maybe you don’t want to worry about your scale when it rains or chemicals spill. Adam’s boast an IP68 rating for 100% protection against water and dust ingress. It’s both resistant to damage and easy to clean, a win-win!

And, despite heavy loads, Adam floor scales, such as our , are able to provide readabilities as fine as 1g. They’re accurate under pressure!

Versatility in Applications

Portability

Because floor scales are generally smaller than full platform scales, they have the added benefit of portability. Many Adam floor scales even boast indicators with rechargeable batteries, so they can be relocated to pits, labs or loading bays as necessary. To ease the moving process, some models can be fitted with wheels in place of the original adjustable feet.

Checkweighing

Adam floor scales also provide a variety of functions beyond simple weighing. Our Gladiator, and boast colour-changing displays for checkweighing, making the results easy to spot from a distance and in low light. This is excellent for ensuring that aggregate bags hit weight targets or cement batches are consistent.

Dynamic Weighing

When weighing moving objects, such as concrete slurries or containers of gas and oil, Gladiator floor scales offer a dynamic weighing function. This calculates the average weight of a moving object over a specified time. Dynamic weighing improves efficiency on the work site as there’s no more downtime waiting for the liquids to stabilise enough for reliable readings.

Label Printing

If keeping reliable weighing records on a busy work site is difficult, Adam’s new is a Touch-Screen Label-Printing floor scale. After weighing an item, simply print out a label and attach it to your cement bags or pre-cut steel beams. The label is fully customisable and can include the weight, date, time as well as a bar or QR code as desired. Then, if you’re not sure what the weight of a particular container of ore samples is, you can simply refer to the label!

Integration

All Adam floor scales feature an RS-232 interface at minimum. Some, like the BTT, offer RS-232 and USB interfaces as standard with ethernet, wireless and WiFi as optional additions. Connect your floor scale to data loggers, PLCs, relays, PCs and printers with ease, gaining improved accuracy, efficiency, traceability and data analysis. This way, you can send weights directly to compliance reports or even feed live data into your production system!

Check out our blog on why connectivity is so important for weighing scales here.

How Floor Scales Can Help

With floor scales, you can weigh a variety of mining, construction and heavy industry items such as:

- Ore, coal & aggregates - guarantee enough samples for thorough material research

- Bulk & raw materials - Weigh the items you use for improved inventory counts later

- Machinery - Ensure parts meet load specifications before installation

- Fuel & Chemicals - Important for safety and avoiding spills/overloads

- Items for transport & shipping - Avoid overloading cars and lorries with materials

While simultaenously enjoying the benefits of:

- Keeping within environmental or transport regulations

- Measuring production output more effectively

- Managing inventory more efficiently

- Improved truck safety

Looking into floor scales but not sure which one is right for you? Contact the Adam team -- we're happy to help.